I’ve been on this scenario many instances: I put together to begin resawing and measure the board’s thickness to search out out I’ve simply sufficient materials to yield what I want. I usually permit myself 1/8 in. of additional materials to joint and airplane a resawn board flat. Typically there’s greater than sufficient thickness; different instances I’m just below my 1/8-in. purpose. Whenever you’ve chosen a selected board on your mission, chances are you’ll take the danger of resawing and hoping for the most effective. Otherwise you would possibly do this approach described in Bruce Hoadley’s Understanding Wooden. Utilized by kiln operators, it signifies the interior stress in wooden. He calls these stress sections, whereas it’s extra generally known as a prong check.

The unique use of this system was to examine for case hardening whereas drying, however may be translated to be used in your store. Many woodworkers already know methods to learn grain to anticipate stress or rigidity, however there are circumstances the place improper drying methods will have an effect on a seemingly steady board. This straightforward technique will help you examine for stress alongside the width of the fabric you employ. It is very important be aware that this doesn’t point out any anticipated motion over the size of a board.

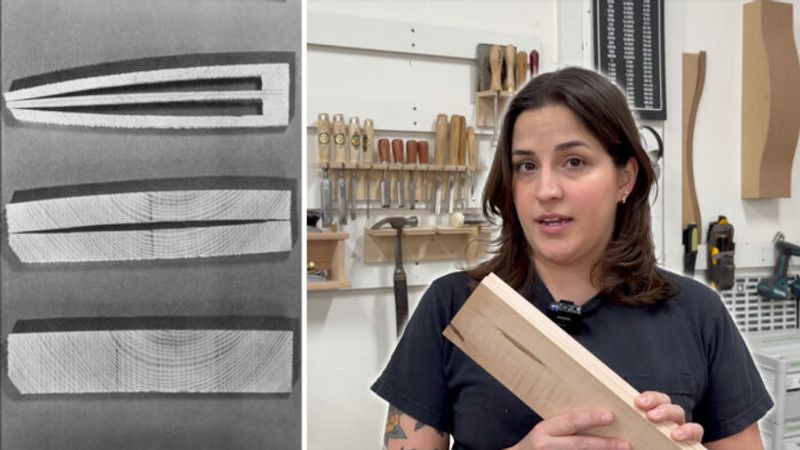

Step 1: Slice

Reduce a small part off of 1 finish of your board. The outcomes are even higher for those who’ve lower your board to tough lengths first, and take a piece from the center of the board as a substitute of finish grain. The ends of boards are essentially the most uncovered to adjustments in moisture, and isn’t as indicative of any rigidity or case-hardening in your materials . Taking a piece from the center of the board will reveal precise inner stresses, if there are any. I’ve discovered a 1/4 in. slice is simply sufficient to get correct outcomes.

Step 2: Make a fork

With the top grain going through up on the desk, waste away the center of the block, leaving two prongs. The prongs ought to be a couple of 1/4 of the thickness of the unique materials, however no wider than 3/8. This enables sufficient motion within the prongs to present a extra correct studying.

Step 3: Consider

What occurs to the 2 prongs? Do they level inward, outward, or keep straight? Straight means the fabric is steady and capable of keep flat when resawn. On this specific case, the prongs didn’t transfer, which confirmed me I might resaw the items with none motion points. It’s best follow to let the piece sit for a pair hours earlier than evaluating, as you’ll let materials relaxation after breaking it into smaller items. In or outward could point out there’s stress or rigidity, and which will imply you’ll have to resaw the fabric thicker so as to have the ability to mill it flat.

Step 4: Resaw

Resaw your materials, evaluating your kerf line as you chop along with your bandsaw. Any pinching or separating of the fabric whereas resawing might point out stress alongside the size. This trick will hopefully take a few of the guess work out of milling, and help you resaw materials with confidence.

Join eletters as we speak and get the newest methods and how-to from Fantastic Woodworking, plus particular presents.